Client: CYP Design & Construction JV (Lendlease, John Holland and Bouygues Construction Australia)

Metro Tunnel – Melbourne, Victoria

OVERVIEW

The Metro Tunnel Project is a metropolitan rail infrastructure project currently under construction in Melbourne, Australia.

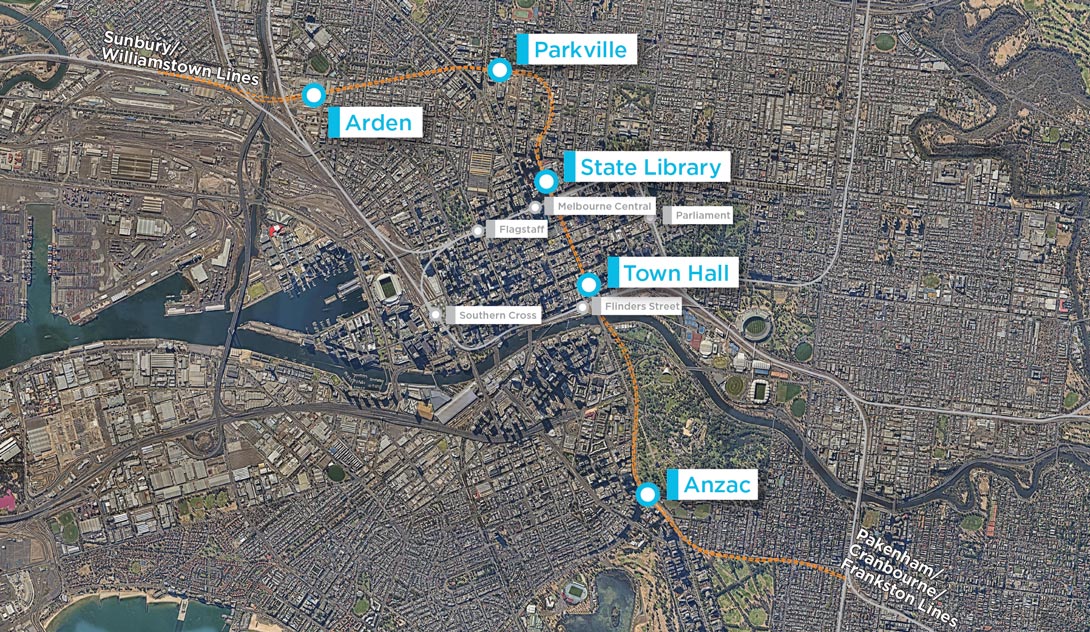

The Metro Tunnel is Melbourne’s biggest rail project since the City Loop was first built in the 1970s. It involves building twin nine- kilometre rail tunnels and five new underground stations from Kensington through to South Yarra. New underground walkways will connect the new CBD stations to the City Loop, and once complete the Metro Tunnel will help move 504,000 more passengers across the network during peak periods, making it easier to move around the city.

The Metro Tunnel Project’s Tunnels and Stations works package is being delivered by CYP Design & Construction, a joint venture between John Holland, Lendlease and Bouygues Construction Australia.

KEY FEATURES OF THE PROJECT

- Twin nine-kilometre rail tunnels from the west of the city to the south-east as part of a new Sunbury to Cranbourne/Pakenham line.

- Five new underground stations:

- Arden

- Parkville (under Grattan Street)

- State Library (at the northern end of Swanston Street),

- Town Hall (at the southern end of Swanston Street)

- Anzac (under the Domain Interchange on St Kilda Road).

The two stations under Swanston Street will be directly connected to the City Loop at Melbourne Central and Flinders Street Station.

GENERAL INFORMATION

- Location: Melbourne, Victoria.

- Lead Contractor: CYP Design & Construction joint venture between Lendlease, John Holland and Bouygues Construction Australia.

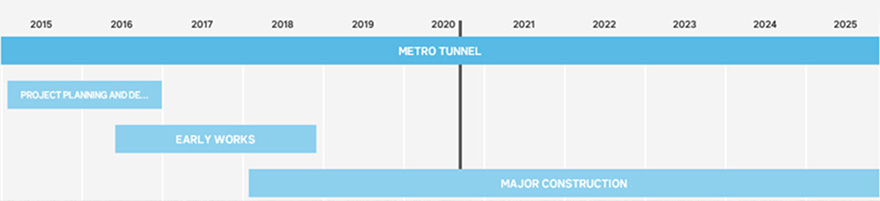

- Timeline: Major Construction 2018 – 2025.

PROJECT TIMELINE

ACROW’S ROLE & ENGAGEMENT – MULTIPLE CONTRACTS IN RELATION TO THE FOLLOWING STATIONS & ASSOCIATED SECTIONS:

Arden Station

The engineering, design and supply of the equipment in relation to:

- Circular void formers for the tympanum wall which provides entrance to the tunnel and where the TBM commences tunnelling.

- Inverted walls / Tympanum Head wall (Single Sided Wall System)

- Single sided Walls up to 8.70 Mtrs (Single Sided Wall Systems)

- Supply of Acrow GASS for the concourse roof slabs support for the east and west sections of the station

- Supply of Acrow-80 for supply of internal walls to the top of the Concourse slabs

Town Hall Station

The engineering, design and supply of the gear in relation to:

- Ground floor slab support using Acrow Supercuplok.

- Internal wall forms, Shaft forms, Reverse blinding wall forms and Single sided walls.

State Library Station

- The supply of the System Gantry for the Tie Beam and Roof Beam Gantry.

Parkville Station

- The supply of Void Formers for the TBM (Tunnel Boring Machine) cradle and launch platform.

- The supply of hardware and consumables direct to the subcontractor on site.

Anzac Station

The engineering, design and supply of the gear to Ardreagh Formwork in relation to:

- Circular void formers for the tympanum wall which provides entrance to the tunnel and where the TBM commences tunnelling.

- Inverted walls/Tympanum Head wall (Single Sided Wall System)

Eastern & Western Portals

- Engineering, design and supply of Void Formers, Single sided walls, Slim Max Soldiers and Accessories direct to the managing contractor and sub-contractors such as Astern, Ardreagh, Speedpro Industries for the Eastern and Western Portal shafts.

Engineering and Design

- More than 3000 hours and counting.

SUB CONTRACTORS ENGAGED ON THE SITE

- Speedpro Industries Pty Ltd.

- Ardreagh Formwork

- Astern Group Pty Ltd

- Connor Concrete & Formwork Pty Ltd.

ACROW GEAR UTILISED ON THE PROJECT

- Acrow Powershore – Heavy Duty Support System.

- Acrow GASS – Heavy Duty Support System.

- Acrowall-80.

- Acrow Supercuplok.

- Acrow Slim max Soldiers.

- Timber, Ply and Accessories.

- Acrow Props.

Acrow were engaged on the Metro Tunnel Project to provide a self-propelled ‘double’ dual purpose gantry.

This gantry will twice travel the entire 250m length of the main cavern at State Library Station currently under construction in Melbourne’s CBD, and enable the upper level tie beams to be formed at a height of 14 mtrs. Once complete the upper section is removed and adapted to accommodate an additional working platform at 8 mtrs. This lower level platform then enables the lower level roof beams to be formed. The motorised travelling of this gantry between pours takes only 15 minutes, enabling other works to continue.

This is the first time Acrow have provided a ‘double-decker’ dual purpose gantry where effectively the top section is removed to reveal a lower level gantry for a secondary function.

The sub-contractor team who assembled this gantry on site “Connor Concrete & Formwork” commented on how simple the system was to assemble.